YOUR COLOR.

YOUR VIBE.

YOUR VINYL.

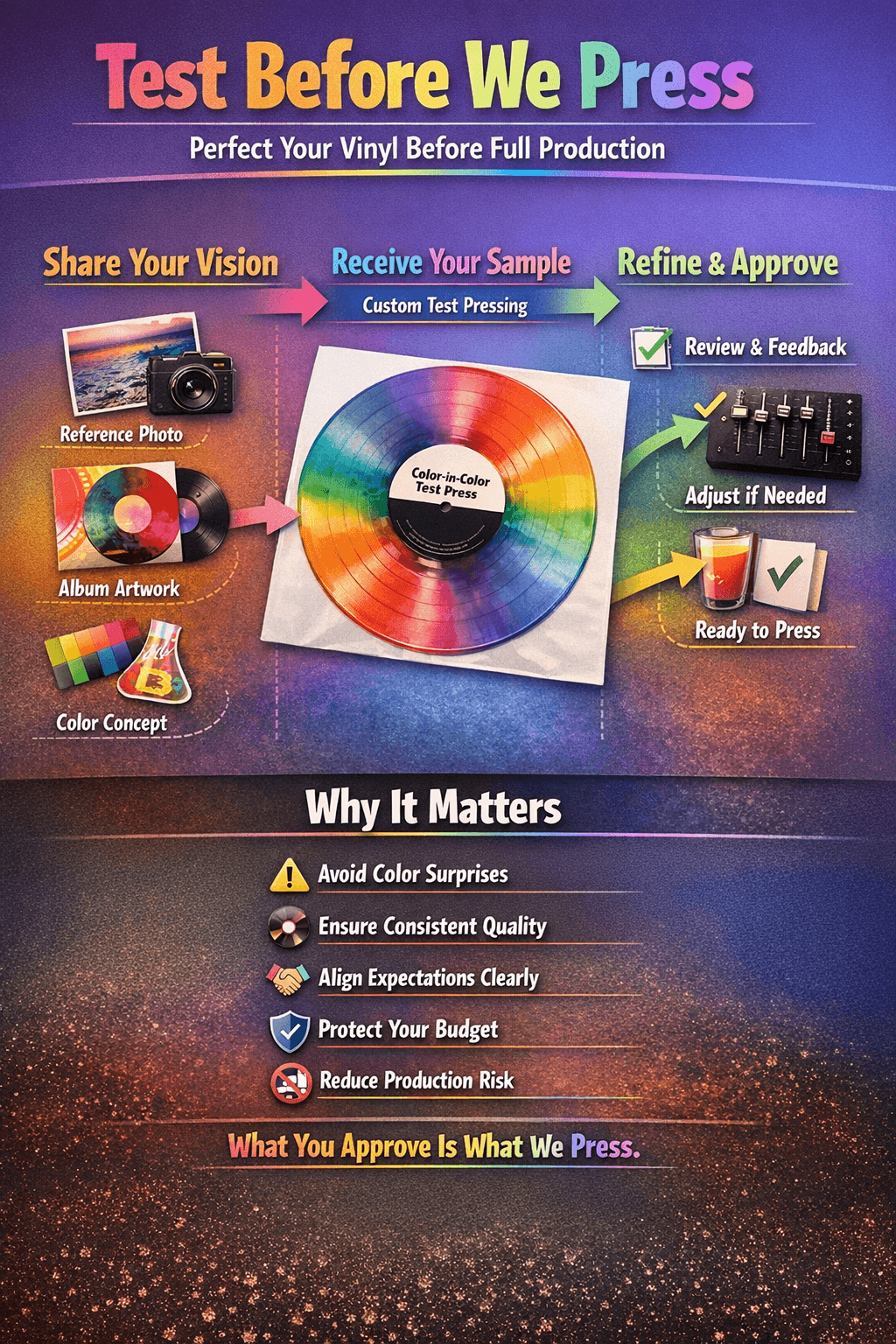

Before we press thousands, let’s create the one that feels right.

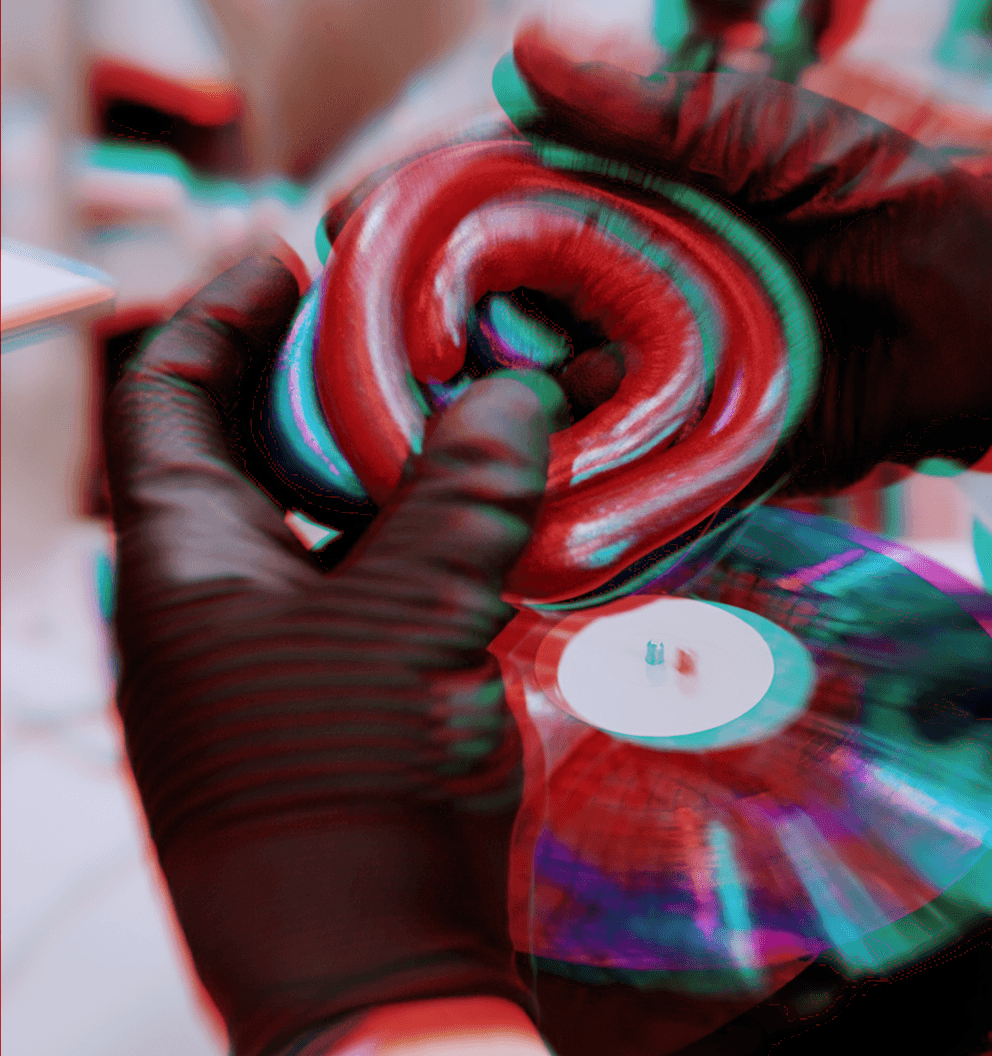

We turn your album artwork into real, physical color.

Not mockups. Not screen simulations. Real vinyl.

We accept the imaginal ideas from the customers, we build the unique vinyl for you. From the proto design, to the color effect sample to proof. After the confirmation from the customer, we will start the mass production and deliver most competitive products to you.

1. No More “Hope It Looks Good.

Too many vinyl projects jump straight into mass production —

only to realize the color feels off.

Too dark.

Too muddy.

Too safe.

Too different from the artwork.

You don’t approve a file.

You approve a record in your hands.

2. Co-Creation

We Don’t Just Press Records.

We Design Them With You.

Send us your album cover.

Tell us your vibe.

Is it dreamy? Aggressive? Minimal? Neon? Nostalgic?

We analyze the color palette and build:

- 2–4 experimental color structures

- Different transparency levels

- Smoke / Marble / Splatter variations

- High saturation youth-focused tones

We test.

We tweak.

We refine.

Until it hits.

3. Pick Your Energy

Tell us what you like to have, which style of the vinyl you prefer and the colors.

Adjustable density.

Adjustable balance.

Adjustable drama.

4. From Artwork → To Actual Vinyl

1️⃣ Upload Artwork

2️⃣ Color Concept Design

3️⃣ Test Press Sample

4️⃣ Feedback & Fine-Tune

5️⃣ Lock the Final Version

6️⃣ Go Into Production

No surprises. No mismatches. No regrets.

Let’s Build Something That Stands Out On The Turntable.